Is that a motorola moto z2 play? I owned that phone and I used to disassemble it just like this!

Edit: saw in another comment that it's a z4. The camera did look strange for a z2 at a second glance

Is that a motorola moto z2 play? I owned that phone and I used to disassemble it just like this!

Edit: saw in another comment that it's a z4. The camera did look strange for a z2 at a second glance

While I don't remember his name, I remember there was a Darknet Diaries episode about the researcher who first investigated the problem. The episode was very thorough, I liked it a lot. I also don't remember the name of the episode, so I guess this comment is kinda useless

Ah, good old PlarformIO

Others are saying to switch to the specific driver for your printer. If you do not want to go proprietary you could try and see if your printer is supported by the splix driver

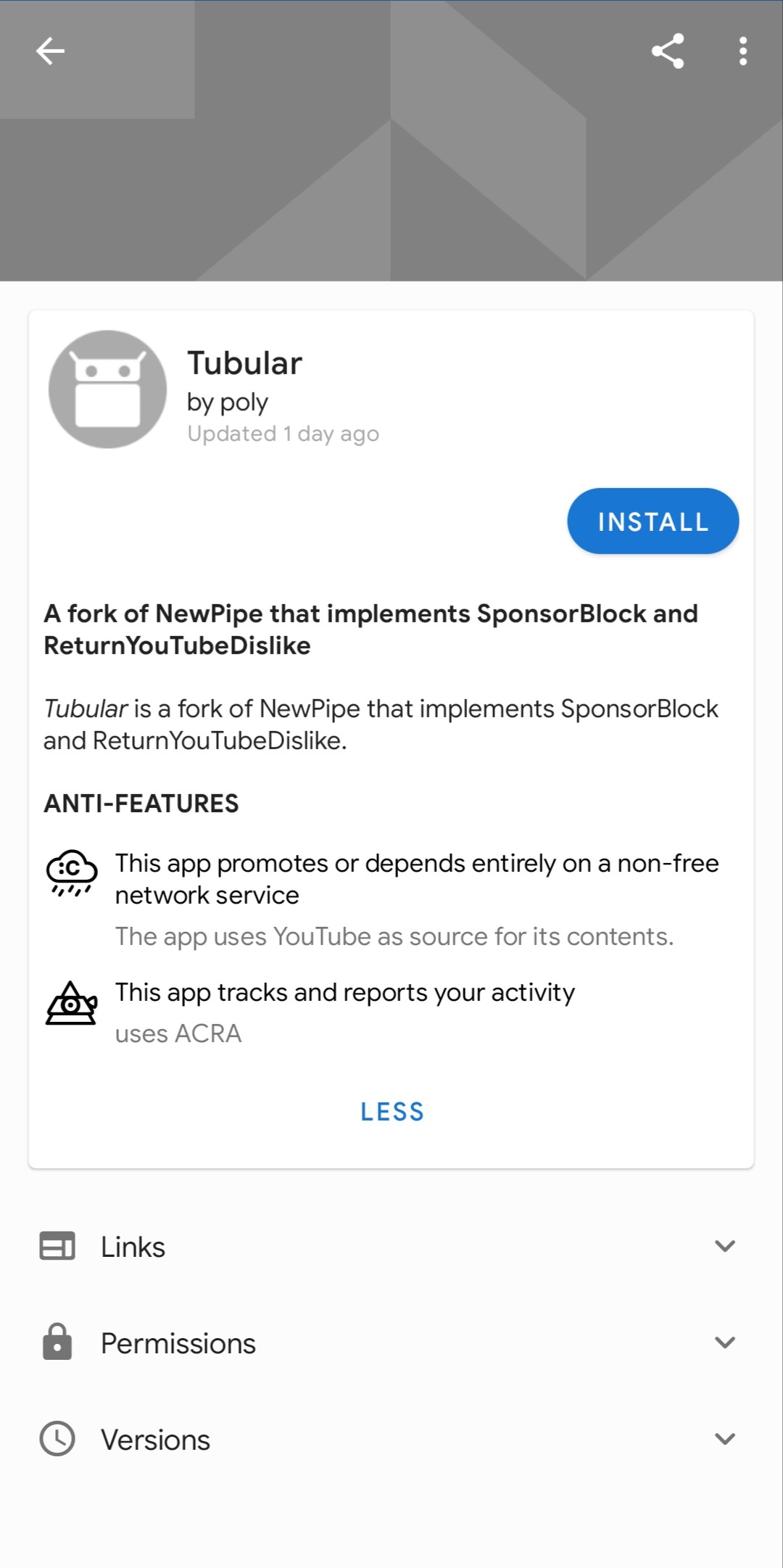

What's up with the in-app tracking? Is it just related to likes/dislikes?

I really despise the use of the mouse, in some way it just feels somewhat wrong, especially the need to constantly move one hand between the mouse and the keyboard. Also I'm way faster at typing that I am pointing and clicking around looking for the right button to press. Terminal commands offer a simple and expressive way to interact with the computer.

What do you use now?

That was the Motorola Moto Z series for ya, had pins on the back for modules to be attached. Some modules were a battery pack, jbl speaker, a projector, and even a little printer to have the phone work like a polaroid

Simply don't. Powering the RPi via the gpio is possible but bypasses all protections (over/reverse voltage, shortcircuit). Do it only if you know for sure that those things won't happen. Otherwise, know that you might kill your pi.

If you still wanna do it, look for ground (gnd) and a +5v rail on the ender 3 board. The here is the rpi gpio pinout, you have to connect gnd to gnd of the board and +5v to the +5v rail on the board.

I guess a good compromise would be to connect the +5v coming from the ender 3 to the proper pads/vias under the microusb cable on the pi, that way you would still have all the protections in place on the pi. But I have never done that, so don't quote me on that.

I run it on oracle cloud always free tier, it's the only service I run there. I just let it oing my subdomains every 2 minutes and send me notifications on telegram. But I don't think that's a solution for you, since you don't want to use a vps

yt-dlpinside termux?