Ty, used spray oil, seemed to work ok

I forgot i had this, will try it though the frequency is probably lower than what you suggest.

Thank you for the advice. Do you really think a toothbrush will work? ^^ I read somewhere that oil spray (you know for pans and stuff) was good, so i tried that and it seemed to work fine, the form slipped pretty easily.

I want to make a drain where this puddle forms, but stock drains from hardwarestores expects more difference in the ground levels. I only have a few centimeters to work with to a french drain around the corner, so i want the outlet to be on the side close to the surface. I have a drain grate that will fit on top of this thing.

Well i just tried holding the bottom of my multicutter onto the mold, probably was not enough. Maybe if i put the entire thing on a plate i can vibrate the whole plate somehow…

I get what you’re saying, but still… why did they put an OLED screen on it?

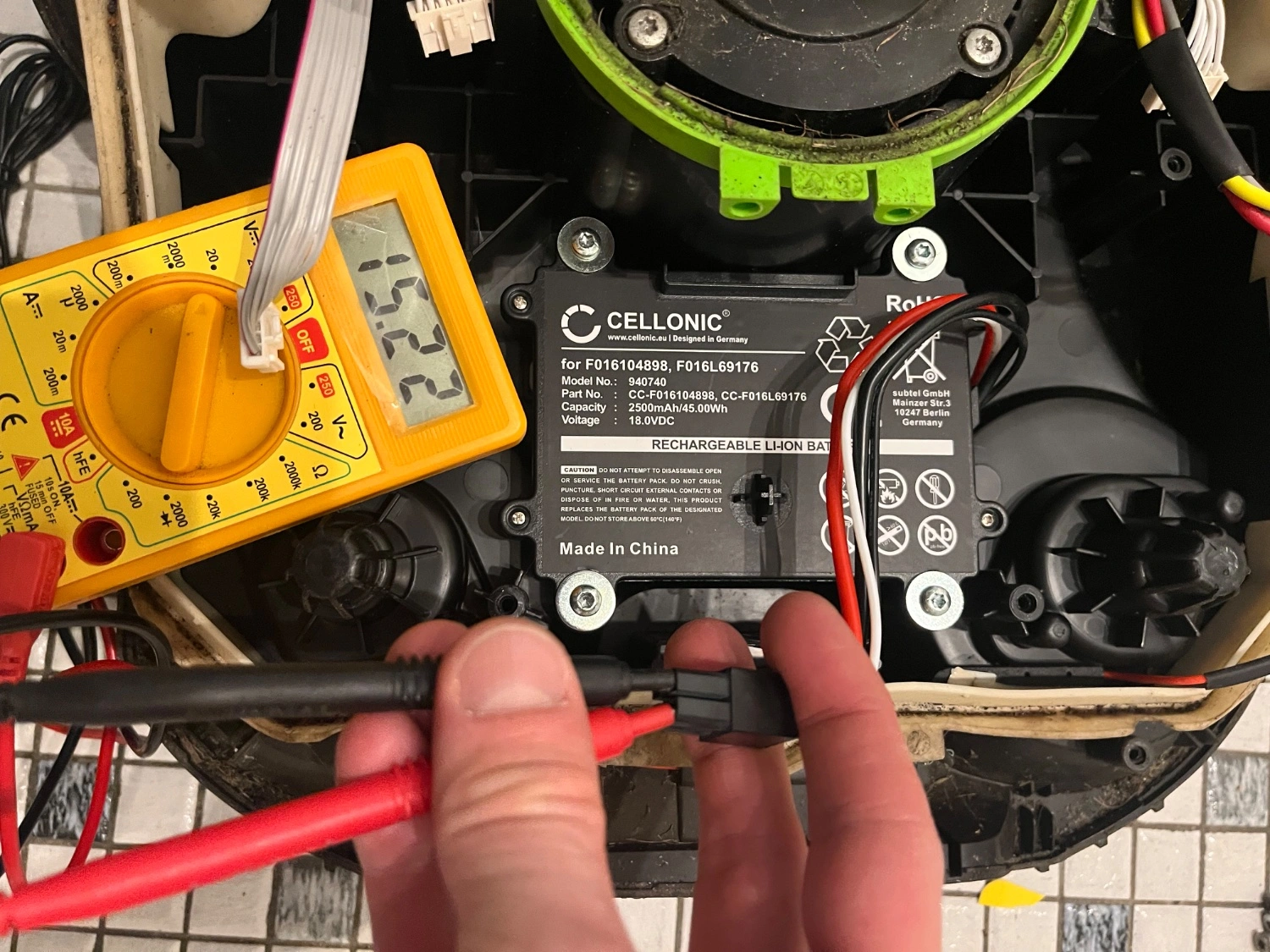

Thank you all for the responses. I ended up ordering a replacement battery, since i intend to sell the unit and don’t want to pass on a ‘pig in a poke’. Had the voltage been a little higher i would probably have attempted to recharge it.

And also: is a depleted battery more likely to short circuit and overheat?

Nice

Cool. I was of the understanding that a big part of the corneal damages leading to vision loss was due to vascularization. I was missing some perspective on that in the article.

Thank you for the elaborate response. The second batch is now vibrated a whole lot more than the first one and i weighed the mixed beforehand. It’s just a premixed bag for setting posts i’ve used. 0-8mm. It’s really a pleasure to see the concrete vibrate into place. I am curious whether i’ve now also vibrated the pour down between the two parts of the mold too… We’ll see in a few days i guess.