Just imagine what they would face in Europe, where workers even have rights!

Teaching the Asian colleagues the fine art of blocking factories and burning tires.

I'm reminded of the time Walmart tried to enter Germany with their work culture. But in their case it wasn't just that the Germans didn't like it. It was illegal. And the German customers were weirded out by Walmart employees smiling and being so cheerful all the time.

Apple still tries to have the cherry up-beat customer services department in the UK and it doesn't work. It's a Saturday, no one wants to be doing this call, don't pretend otherwise it's weird.

This makes me laugh because I work for a UK company that was bought out by an American company, who's trying to treat the UK staff how they would treat US staff - and it's not going well.

Our American colleagues cannot fathom how much time we take off for holidays, especially around Christmas. They also got a shock when doing some recent "restructuring" they couldn't just fire a bunch of UK folks.

Our American colleagues cannot fathom how much time we take off for holidays

So many days if it’s like colombia. They have 37 holidays off each year. It’s great but im constantly forgetting which days are festivals so i always end up walking to the store and then returning home dejected because i couldn’t buy my cheese.

In china I had a UK roommate. He was on the phone with his mom mid week when she should have been at work. I asked if she was sick and he was like "No. She took some vacation days to tidy the house." My jaw hit the floor. My vacation days in the US were so precious and so few that I'd never fathom using any to do chores. Unreal that you can have so much vacation you'd elect to spend it doing chores.

Sounds like the time Walmart tried to get a foothold in germany. Their american way of treating workers, but especially their way of treating customers (greeters at the door) crashed and burned hard here.

Happy workers are hard workers, treat them like shit and they'll walk right out the door.

Correct! Well unless, they're starving and need to feed their families.

Aren't the machines TSMC uses made in the Netherlands? They're the only ones who can get down to that size, and they do it working 36 hours a week...

My brother worked for such a Dutch company (ASM) and often got sent overseas to supervise the setting up of the production lines with these machines.

He mentioned when he'd get sent to Asia, the workers would make sure to get it done over a weekend, while implementing the same setup would take 2 to 3 weeks in the US. In part that was due to the working conditions mentioned, but also simple lack of planning in case of the latter (things would grind down to a haalt because certain changes would need to be made, and the person responsible for the decision wouldn't respond for hours or days, etc).

Side note: while 36 hour work weeks are common in the Netherlands, 40 hours is still the norm in my experience.

3 new chip fabs open recently around phx, which is in low-altitude desert, has had water supply issues for so long there's a canal running from the Colo river through it all the way to Tucson.

Which is fed by a reservoir so low they find old mobster kills in barrels and might have to stop making power.

Why so stupid and short-sighted?

Ah, "faith-based".

And a Republican governor made the deals. Who also allowed water to be used to grow alfalfa that's sent to Saudi to feed their horses.

$$$ + no sense

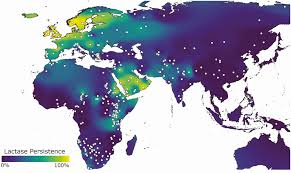

Cows not horses. Peninsular Arabs are some of the few populations on Earth with the mutation that allows for lactose tolerance among adults. It developed over millennia of having nothing else to consume.

76% of AZ water use is for agriculture, but that's besides the point. I've read that most of the water used in a fab gets recycled, so once up and running, water usage isn't as much if an issue as you'd think.

Not a surprise given that worker rights are practically non-existant in the East.

Still wild that TSMC thought they could pull that on western workers. I hope they realize it's not gonna happen and rethink their processes.

Similar stuff happened with US companies in the EU.

That stuff even happens with UK companies taking over German companies. They think they can just fire the members of the working council, very bad mistake! Remember, if you go to another country, you have to adjust to their law.

if you go to another country, you have to adjust to their law

Big business knows no national boundaries. They'll build factories wherever labor is cheap, put headquarters wherever the taxes are low, and sell their wares wherever consumer rights are weak.

Really? Nobody at TSMC thought to google “biggest mistake companies make when opening US plants”? Because this has all happened before

I remember watching a documentary a few years ago where this exact situation happened. Chinese company buys American company, tries to establish their work culture and it just doesn't work.

It’s the same the world over. I’ve worked for years for a western company which has got a large part of their business in Asia and China.

You try taking our “western ways” of leadership to China and see how well it fares; what I would consider “leaving space for a leader to operate and feel accountable” is seen as “my leader has no fucking clue what he is doing; he never tells me what he wants me to do”.

Culture eats everything for breakfast. As a western leader in China you have to act like a controlling maniac (in my cultural frame) to be seen as an effective leader in China.

And it goes both ways. My brother reports to a Chinese manager transplanted to the west and she “desperately wants to micromanage everything” according to the western team.

We are all trying our best.

Probably American Factory from 2019. Definitely a recommended watch for anyone unfamiliar with the topic.

perceived abuses

Way to be passive aggressive, haha. Next they'll be apologising "we're sorry you feel that way" :P

It doesn’t mean that the US factory is any less capable. What needs reworking is meeting the expectation and planning for contingencies. There should be ongoing shifts, specialized teams, rotation, mitigation, etc. I think our output is comparable but it’s done more safely and sustainable over a longer time VS grinding workers to dust and replacing them.

It's not about capabilities, it's about cost.

If you can exploit your workers, pay shit wages for long hours, you'll get a cheaper product. You can get the same output by applying higher standards, but that would mean hiring more people.

The more time i spend in manufacturing environments ( I spend all my time there) the less i see actual product being the finished good. Business are setting themselves up for this autopilot pipe dream of "AI gonna fix everything" marketing/engineering utopia and in reality all it's doing is dividing your operations crew and management. They are neglecting equipment, default mode of compliance is non compliance because of awful processes and quality cutbacks (staffing staffing staffing) and at the end you get a product that's probably not gmp but who cares it's shipping.

That's the nature of capitalism.

Look at healthcare, software, construction. Unless there's a very clear incentive to produce high quality (laws or enforceable contracts) things will go lower and lower in quality.

And unfortunately, a lot of consumers don't care all that much about quality. They want crap that looks fancy.

This last job (I'm a contract employee) will be my last in MFG. I was hired long term (2 years) to get a gsk/haleon site to add almost 40% more deliverables. 280 million units a year to 400 million. Reduce waste by 25%, CoA/CoE turn around down to 2 weeks from 6.

The labs, which operate almost entirely as a community (eg no real rigid structure, lots of senior empires) killed it. 7 day turn around which honestly now my mind. Packaging was a struggle once i pointed out that OEE can be improved by scheduling downtime rather than just oopsing it (strictly beancounter bullshit).

Manufacturing... Took my ideas, literally threw them in the trash in front of me and said they have experts from multiple countries, they don't need my help. Cool, i still get paid so whatever. You wanna see the biggest dumpster fire ever... Laid off about 40% of the mfg work force, rolled out some bullshit trainings about operators and maintenance working to bring equipment "back to new" whatever the duck that means (means maintenance budget is gone) all while investing 0 dollars into repair and maintenance. Gear boxes leaking oil into overflowing catch cans for months. Vacuum traps actually pulling ingredients out of the batches, building more systems upon systems that they can't validate. Cleans that won't pass swabs, cleans that aren't validated, processes that rely 100% on operators to transcribe SCADA data into an electronic batch record system.

Never seen anything like it but i know when a horse is dead and this one was dead before i got there.

As a software engineer, this is exactly how software works.

Everything is just a huge mess bolted and duct taped together, sometimes over decades. And it's all way too complex to understand and crap like crowdstrike happens.

You can't rely on anything anymore and I'm pretty sure, our highly interdependent world will come very close to collapse if anything major happens. Covid was a warning shot, but nobody heard it.

largest microchip manufacturer on the planet

front entrance looks like an abandoned 80s era mall

They just built this! I mean not everything has to look like a cybertruck but why does it already look 40 years old

I work in a fab and it's pretty industry standard to run 12 hr shifts for operators (3 on 4 off then 4 on 3 off) and if your in engineering or IT be ready to be on call cause they don't want a 20-100 million+ machine down any longer then absolutely necessary.

I also work in a fab. We have the 3-4-4-3 rotating shift pattern just like everyone else, but we don't treat our people like cattle, unlike TSMC. We also tend to slightly overstaff, versus TSMC that understaffs and drives their people harder to make up for the difference.

IT be ready to be on call

Pretty standard for all systems IT

Im IT on call.

They call, and call, and call. I game and hike and sleep. Monday, I email them the part of my contract that says "best effort to respond after hours when available"

Turns out I'm rarely available.

Reminds me of the Netflix show “American Factory” about a Chinese factory opening in the US.

Quite a fascinating clash of cultures.

While TSMC is considered by many in Taiwan as the pinnacle of engineering jobs, other companies in Arizona are competing for that labor pool. Intel, in particular, is expanding its Arizona chip factory.

Ya, so about Intel.....

Same thing happened when Kia entered Europe. Unusually low pay combined with mandatory morning employee marching and exercising in the factory, combined with threats of physical punishment for "under performing" workers.

I hope they can be held accountable for mistreating those 'transplants" (what an ugly word!) too. But I guess that would be easier here in EU than in USA.

So what happens to Taiwanese manufacturing when their population collapses due to a super low birthrate. They right behind South Korea in lowest TFR.

W for workers rights, L for US fab production

Technology

This is a most excellent place for technology news and articles.

Our Rules

- Follow the lemmy.world rules.

- Only tech related news or articles.

- Be excellent to each other!

- Mod approved content bots can post up to 10 articles per day.

- Threads asking for personal tech support may be deleted.

- Politics threads may be removed.

- No memes allowed as posts, OK to post as comments.

- Only approved bots from the list below, this includes using AI responses and summaries. To ask if your bot can be added please contact a mod.

- Check for duplicates before posting, duplicates may be removed

- Accounts 7 days and younger will have their posts automatically removed.