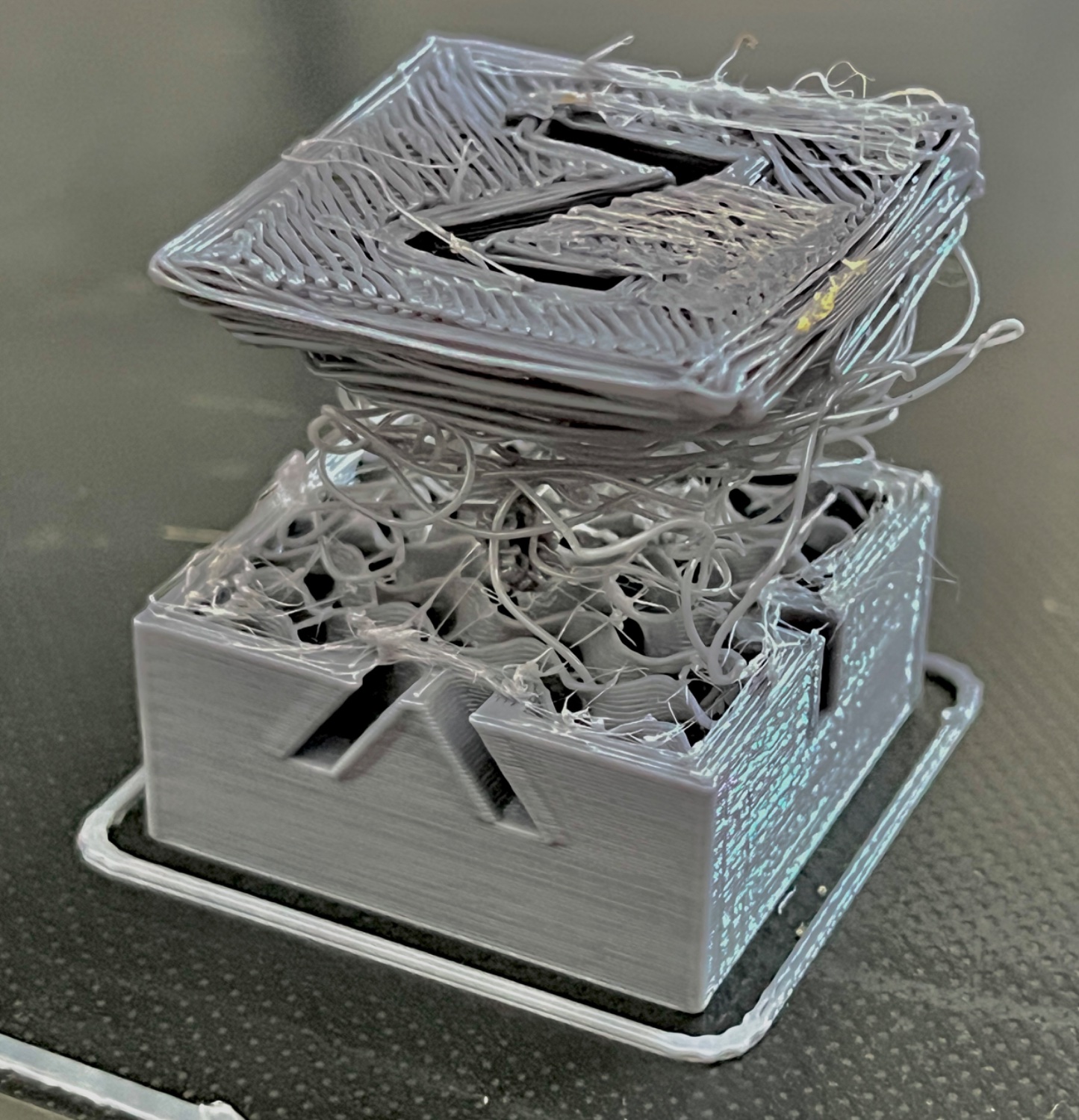

Thats pretty amazing tbh. You could call that art imo. Like in some philosophical "Building yourself back up after failure" type of way

That is a work of art.

Definitely belongs on the wall of “this should be shame but I’m really quite proud”

We all have that shelf, right?

I used to have it but then i just had to throw everything away. Something something why is this junk in our house something something angry wife…

Put it next to your live laugh love poster

Boi-oi-oing!

Here is an alternative Piped link(s): https://piped.video/hoS1MCF8AeI?si=cP9DUvUIIe6KMJ0V

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source, check me out at GitHub.

I was just at an art exhibit last week, and I'm confident you should put this in an exhibit. It perfectly represents the stages of a website or software project.

Anyone aware if that be re-melted or recycled back into filament, or is it pretty much done for?

If I had a 3D printer this would be nightmare fuel after waiting X hours for the print to complete lol

In theory, you can remelt. Unfortunately, the practicalities mean it's not viable. Each remelt cycle degrades the plastic itself, so you can only put 20% or so 'old' plastic into the mix. Combined with the game of plasticisers (to remove brittleness) and reliable forming, even commercial systems struggle, let alone home ones.

If environmental concerns are the issue. It's best to print in uncoloured PLA filament. PLA is corn starch based, and decomposes in a bio reactor environment (it rots quickly in an industrial composter).

As for speed. They are getting impressively fast. A calibration cube takes around 20 minutes, though less than 5 minutes is possible. My machine is effectively fire and forget. They mess around while you are tuning them in, but once you have a good calibration, they now tend to hold it well. You'll sit there watching it in fascination for the first few months, but that wears off.

You get used to that being a possibility with every print. That’s why you should do everything in your power to have your printer always in shape and operational, although sometimes it will happen no matter what!

Unfortuneatly, this is just waste, straight to the bin.

Is it still a 20mm cube?

This was max acceleration / max speed test, it’s a 30mm cube (scaled)

Not really a cube, that's certain.

But unless it's losing steps, the printer just can't make that top layer in any other height.

Clearly your Printer is not an Elon Musk fan.

I don’t get it 😔 Care to enlighten me?

You tried to get it to print an X and it noped out.

Aahh okay! That’s actually funny now when i think about it a bit!

I'm guessing cause it stopped printing the "X"

X? No, Ctrl+Z

Ahhh I see… the good old spaghetti infill exposing

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible